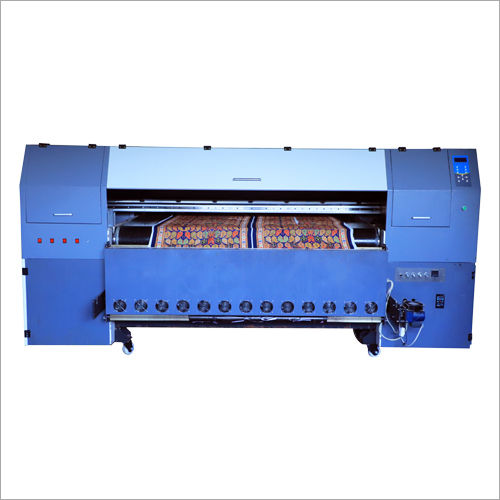

Konika1024i DIRECT FABRIC PRINTING

850000.00 INR/Unit

Product Details:

- Printing Width 1800 mm

- Printing Method Direct Fabric Printing

- Automatic Grade Automatic

- Product Type Printing Machinery

- Head Size 1024i

- Dimension (L*W*H) 2780 mm x 1120 mm x 1500 mm

- Condition New

- Click to View more

X

Konika1024i DIRECT FABRIC PRINTING Price And Quantity

- 850000.00 INR/Unit

- 1 Unit

Konika1024i DIRECT FABRIC PRINTING Product Specifications

- Automatic

- 2780 mm x 1120 mm x 1500 mm

- Printing Machinery

- 1024i

- 1800 mm

- Direct Fabric Printing

- Up to 120 sqm/hr

- Industrial

- New

- 50 Kilograms (kg)

- Multi color

Konika1024i DIRECT FABRIC PRINTING Trade Information

- Cash Advance (CA)

- 10 Unit Per Day

- 1 Days

- All India

Product Description

We serve the most efficient Konika1024i DIRECT FABRIC PRINTING which runs efficiently on low power. It has better results than screen printing or other method. With this printer, the ink is allowed to permeate the fibers of the products material. At industrial levels, the dye sublimation technique is most successful; thus, the printer is perfect for such purposes. In adherence to latest standards for manufacturing of Konika1024i DIRECT FABRIC PRINTING , we are producing the finest performing printer. It needs low maintenance and has higher durability.

Advanced Printing Technology for Textiles

The Konika1024i Direct Fabric Printer incorporates cutting-edge Konica Minolta 1024i printhead technology, delivering high-definition results across a spectrum of fabrics. Its selection of ink types-reactive, pigment, and disperse dye-supports unparalleled color vibrancy and fabric compatibility, making it perfect for industrial textile businesses aiming for quality and versatility.

Efficiency Meets Precision

Automatic feeding and take-up systems streamline production, while the intuitive RIP software simplifies print management. The printer operates at impressive speeds up to 120 sqm/hr, ensuring large-volume jobs are completed efficiently without compromising on detail or resolution. Its broad printing width and fabric tolerance enable users to handle a multitude of fabric types with ease.

FAQ's of Konika1024i DIRECT FABRIC PRINTING:

Q: How does the Konika1024i Direct Fabric Printing machine operate?

A: This printer utilizes 8 Konica Minolta 1024i printheads to apply ink directly onto fabrics. It features automatic feeding and take-up systems for continuous operation and is managed via included RIP software, ensuring efficient workflow and seamless print management.Q: What types of fabrics and inks are compatible with this printer?

A: The Konika1024i supports cotton, polyester, silk, wool, and blended materials. It accommodates reactive, pigment, and disperse dye inks, enabling versatile printing on various textile substrates for optimal color and durability.Q: When is the ideal time to use this machine in an industrial setting?

A: This machine is best deployed when there is a need for high-speed, high-resolution textile printing, such as fulfilling bulk orders or producing intricate designs requiring vivid color reproduction. Its robust throughput handles demanding production schedules efficiently.Q: Where can the Konika1024i Direct Fabric Printer be installed?

A: The printer is suitable for textile mills, large-scale garment production facilities, and industrial print service providers. It should be set up in an environment with controlled temperature (20-30C) and humidity (35-65%) to ensure consistent print quality.Q: What is the printing process using this equipment?

A: The printing process involves preparing the fabric, setting up the desired design on the RIP software, and loading the material onto the machine. The printer then directly applies ink, achieving resolutions up to 1440 dpi, after which the fabric is automatically collected by the take-up system.Q: How can users benefit from employing the Konika1024i for fabric printing?

A: Users benefit from faster production times, high-definition imaging, compatibility with a wide array of fabrics and inks, and reduced manual intervention due to its automatic features. These factors contribute to cost savings and enhanced product quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Direct Fabric Printer Machine' category

"Dealing in industrial purpose printers only".